Suzhou Jiuyi Hi-Tech Nonwoven Equipment Co., Ltd. (a high-tech enterprise in Jiangsu Province), won the first prize of China Textile Federation Science and Technology Progress Award in 2019, and the 2020 National Technology Invention Award has entered the publicity stage, with 39 invention patents. In-depth industry-university-research cooperation with Donghua University established the "Suzhou Nonwoven and Nonwoven Equipment Engineering Technology Research Center".

The main products are: 1. Complete set of production equipment for electrospinning nanofibers - successively created a spatially symmetrical high-curvature liquid surface electrospinning fiber control theory system and an innovative and precise structure electrospinning non-woven material mass preparation technology, which is currently the world's most sustainable The production line with high production capacity has won the first prize of China Textile Federation Science and Technology Progress Award. The 2020 "National Technological Invention Second Prize" has been announced, and has 76 patents; 2. Air-laid non-woven equipment-mainly used in home textiles and Automotive sound insulation industry. The technical level is relatively advanced in China, with high output (1.2 tons/hour), small weight deviation (CV<5%), good sound-absorbing effect, etc., and has 5 patents; 3. Ultra-high-speed trajectory non-woven equipment production line-acupuncture The frequency can reach 1600 pricks/min, and the production speed can reach 150 m/min. It can replace imported products and has 8 patents.

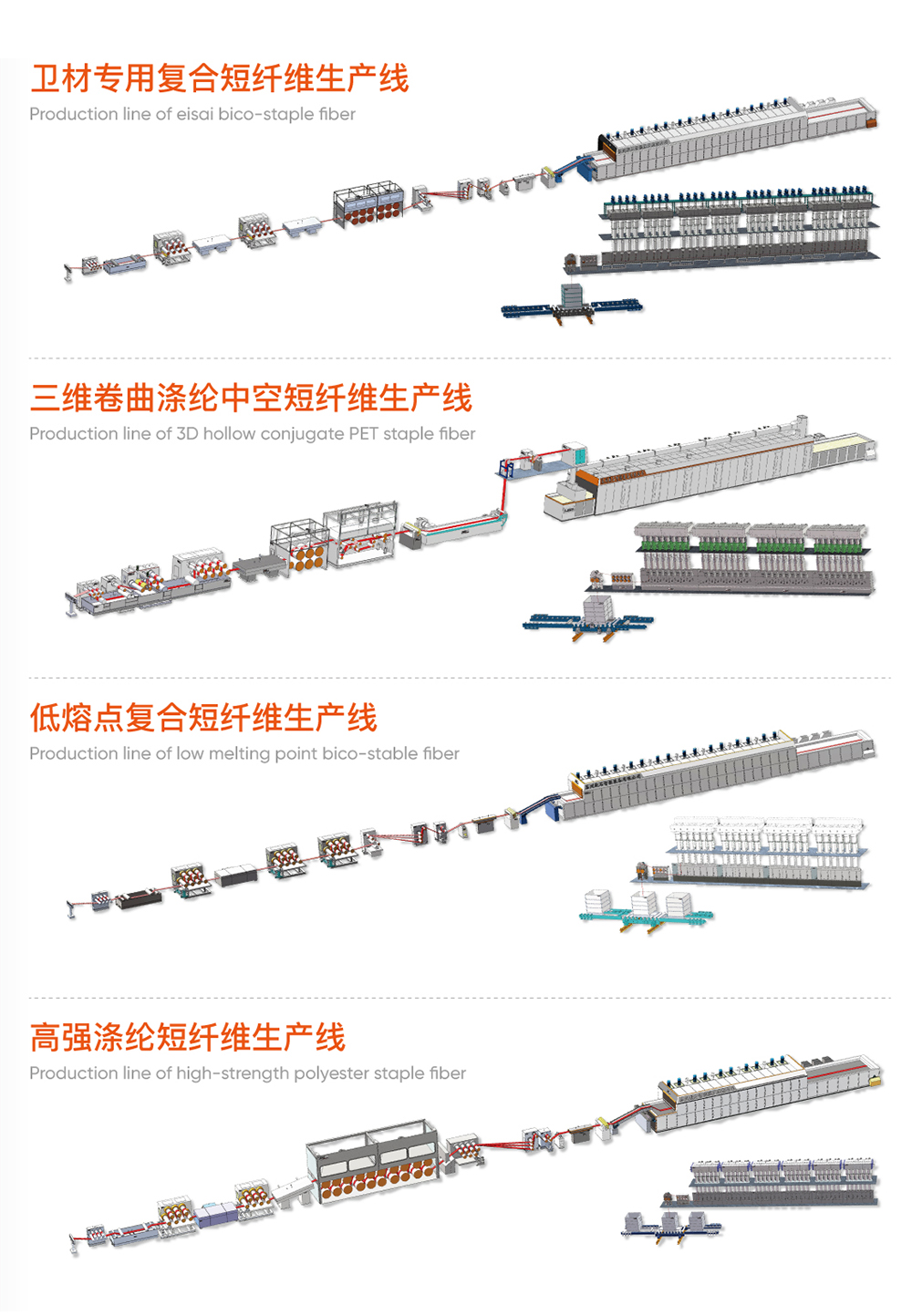

Suzhou Ruanshi Intelligent Equipment Co., Ltd., the project was officially completed in March 2020. It is a start-up technology enterprise that has just entered the trial operation stage. The company integrates digital and information technology, and has successively cooperated with relevant scientific research institutes and colleges The school and large-scale chemical fiber production enterprises have jointly created a R&D and manufacturing platform integrating "production, learning, and research". 14 patents have been applied for and 7 patents have been authorized. The main products are: 1. Large-capacity (more than 30,000 tons per thread), differentiated composite spinning staple fiber complete sets of equipment; 2. Digital high-speed "one-step" fiber complete sets of equipment, with 15 patents.

wechat number:

wechat number:

Service Tel

Service Tel

Tel:0512-52551712

Tel:0512-52551712

Address: Baziqiao village, Zhitang Town, Changshu City, Jiangsu Province (next to national highway 204)

Address: Baziqiao village, Zhitang Town, Changshu City, Jiangsu Province (next to national highway 204)

E-mail:sales@kingcharmcn.com

E-mail:sales@kingcharmcn.com

Wechat

Wechat

Contact

Contact

Telephone

Telephone